Single Rebate Door Frame

They are one of the most used types due to their elegant and contemporary design, ideal for use in internal doors. Single Rebate Door Frames in India are also relatively simple to fit and can be easily coordinated with other forms of door in modern interiors.!

Overview

Single rebate door frames are necessary structural parts in both the residential and commercial buildings, which has a single groove or rebate on the frame periphery that is used to house the door. These frames are available in different sizes depending on the standard size of the doors. The rebate depth is 12-15mm, and thickness of the frame is 1. 5-2. 5mm and corner construction , single rebate door frames are built to meet or exceed the relevant codes and standards of the construction industry .

These frames are manufactured from galvanized steel and provide better weather resistance, better strength, security and easy installation. There is a corner finish featuring embossing and an interlock system with punching and rivets.

Why Single Rebate Door stand out from the rest

• The rebate serves to form a step that enables the door to close tightly against the frame thus minimizing on the drafts and enhancing thermal efficiency. This can be especially beneficial in areas where energy conservation and climate control is a concern.

• Besides, by permitting the door to be flush with the frame, the rebate improves sound proofing between adjoining rooms. This is especially important in places where there is need for privacy or sound proofing like offices or homes respectively.

• Our single rebate doors have been through the hot-dip galvanization process which offers a metallurgically bonded zinc layer that eliminates peel off and offers a superior anti-corrosive layer as per the industry standards.

• The lock system of our single rebate doors has a reinforced strike plate, and heavy-duty hinges that collectively offer the best security. Such an approach guarantees that the door remains locked and offers the highest level of protection against vandalism and break-ins.

Manvik's Single Rebate Door Frames: Where Functionality Meets Aesthetics

Step One:

Rust-Resistant and Refined

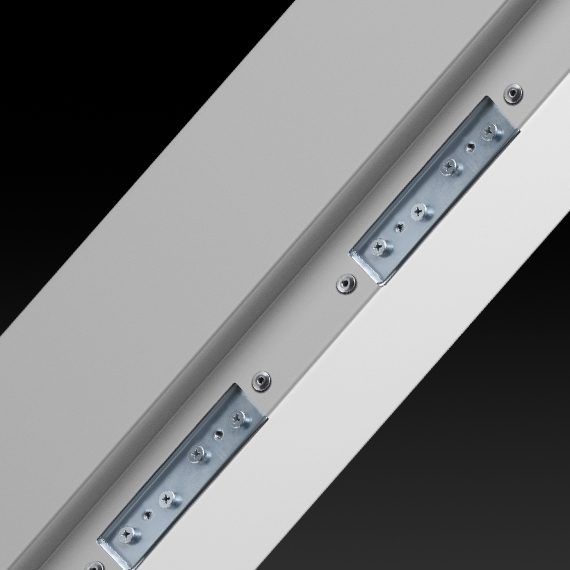

Manvik’s PPGI/PPGL single rebate door frames have a unique design of the vertical and horizontal parts of a frame that are merged in a way that does not require welding or grinding. These frames have their corners embossed and interlocked; the punching and rivets create a strong bond here. This technique of construction is not only perfect for achieving a clean and polished look on the structure but also helps in the longevity of the frame through the prevention of rust.

Step Two:

Secure and Durable Hinge Attachment

Further, the door hinges are attached with the help of rivet technology that does not harm the actual PPGI or PPGL sheet and no more cuts are added that may cause rusting. This method helps to ensure that the door hinges are well fixed and as well will last for a longer time. Inside a plastic cap is provided to protect the hinges while constructing the door from cement or any debris being stuck in there.

Step Three:

Advanced Locking System for Durability

The extensions of Manvik door frames are a bottom channel that strengthens the door frame and is compatible with the lock system without welding. The thick locking groove is covered with a plastic cover during construction, they do not wear out, and the final finish is accurate and strong. All these features collectively help in providing the necessary strength to the frame, ease in installation to the frame and most importantly, the long life of the frame.

What Sets Us Apart

At Manvik door frames, the conventional methods of constructing door frames are raised to a whole new level of quality, design, and workmanship. Here’s what sets us apart:Here’s what sets us apart:

Precision Engineering

The door frames that we use are designed with great care and the rebate style used is single which provides perfect fitting and optimum performance.

Innovative Lock Systems

Security is essential, so our frames feature modern, secure locking systems designed to provide maximum protection and ensure top-level safety.

Custom Solutions

Custom solutions allow tailored design and sizing of equipment to meet precise architectural requirements and specific functional performance needs.

Commitment to Quality

We are dedicated to giving our clients the best quality solution from the drafting table right up to the time of project completion.

Customer Service

Customer service is one of our strengths, and our consultants are always available to guide and assist customers until the end.

Advanced Finishing

Our frames are subjected to through finishing processes such as high grade galvanization, powder coating or custom stains and paints.

Key Benifits

Daily sweeping or vacuuming, weekly mopping, and annual painting or sealing of the floor.

To ensure that there is a close contact between the door and the frame to enhance on weather tightness and security.

Yes, they are good for use in both the interior and exterior of the building.

Latest Projects

Delivering Continuous Value to Our Clients Through Ongoing Product Development and Innovation.

Through our solar division we have established ourselves as the preferred market channel for some of the leading PV manufacturers around the globe. Our solar specialists work in tandem with the partners to improve the characteristics of products, shorten delivery time, and control cash conversion cycle.

Cost Effective

Visual Aesthetics

Good Sealing

Request A Quote

Quick Contact

Precision-engineered for superior style and durability. Explore our PPGI products.

Head office:

Rania chungi, Sirsa, Haryana

©2025 manvik door frames, All Rights Reserved. With Love by bonkersart