PPGI Window Frames

PPGI window frames are widely used in construction because of their durability, resistance to corrosion, and the appearance.

Overview

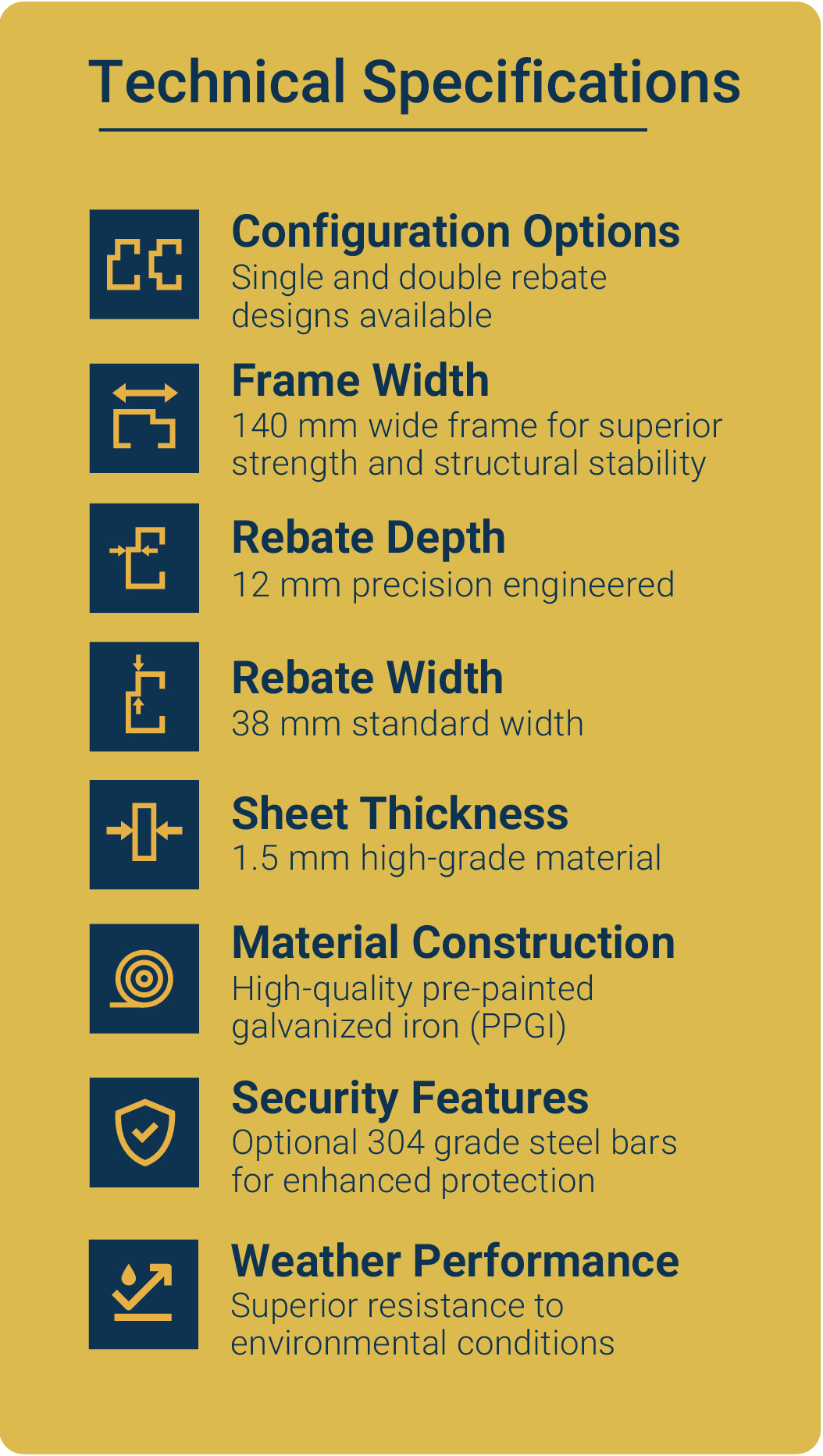

PPGI window frames are long-lasting, easy to maintain and give a good look to the building construction. PPGI window frames are made using a corrosion-resistant galvanized iron core and a pre-painted coating to ensure that the frames are not easily affected by weather conditions hence lasting longer. They come in several different colors and finishes and can be used to add a little more design freedom to a project and can be adapted to fit into various architectural designs. PPGI window frames are also cheaper, easy to fix, and can be made stronger to incorporate security measures. Ideal for the residential, commercial, and industrial buildings, they offer good thermal resistance and are perfect for use by builders and architects who would wish to find a good window framing solution.

Why PPGI Window Frames stand out from the rest

1.PPGI door frames are galvanized with a layer of zinc and are also pre-coated with superior quality paint. This affords them a very good level of protection against corrosion and therefore can be used in areas where there is high humidity or the environment is generally unfriendly.

2. The use of galvanized iron base and the pre-painted surface improves on the overall strength of the door frame. The PPGI frames are highly resistant to wear and tear and as such, they have a longer life span than most other materials.

3. Pre-painted finish of PPGI frames provides better and attractive look to the frames. They come in a number of colors and finishes to suit any architectural design and can be easily matched.

4. The outer layer of PPGI door frames is a protective layer, thus they do not need much maintenance. The paint applied to the steel before fabrication cuts down on touch-ups and re-painting expenses in the future.

Elevate Your View, Enhance Your Home

Step One:

Integrated Frame Design

Manvik’s single rebate window frames are crafted from PPGI/PPGL with an integrated vertical (jamb) and horizontal structure, eliminating the need for welding or grinding. The rebate channels on both jamb and head improve sealing, reducing drafts and enhancing security. Embossed, interlocking corners with strong riveted connections boost durability. A baked-on pre-painted finish prevents rust and chipping, offering a clean, long-lasting, and aesthetically pleasing window frame solution.

Step Two:

Durable Hinge System

Manvik uses rivet technology to fasten window hinges without damaging the PPGI/PPGL sheets, avoiding rust-prone cuts and ensuring long-lasting durability. Hinges are well-anchored and protected by plastic caps that block construction debris. These features simplify installation and improve hinge longevity. Additional hinge caps eliminate the need for resizing during fitting, making the frame easier to install while maintaining a high standard of finish and functional performance.

Step Three:

Waterproof Frame Construction

Manvik’s single rebate window frames integrate vertical and horizontal sections without welding, preventing weak points for water entry. The rebate on the jamb and head creates a tight seal against drafts and moisture. Embossed, interlocking corners and a rust-resistant, baked-on finish enhance durability, offering a sleek, waterproof solution ideal for long-lasting protection in any weather condition

What Sets Us Apart

At Manvik PPGI window frames, we redefine conventional window frame manufacturing with superior quality, precision design, and outstanding craftsmanship. Here’s what sets us apart:

Precision Engineering

Our PPGI window frames use single rebate designs for perfect fit and sealing. Manufactured with tight tolerances, they ensure uniform size, strength, and secure installation—minimizing air leakage, enhancing performance, and fitting perfectly across residential, commercial, or industrial applications.

Innovative Lock Systems

Our PPGI frames feature advanced locking systems with deep, reinforced grooves that ensure a tight, secure closure. Engineered to resist tampering, damage, and wear, they deliver enhanced safety, long-term reliability, and user-friendly convenience—without compromising on modern design or visual appeal.

Custom Solutions

Every project is unique, which is why we offer custom-designed and sized PPGI window frames to meet specific architectural and functional requirements. Whether for residential, commercial, or industrial use, our frames ensure a precision fit, easy installation, and seamless integration.

Ask ChatGPT

Commitment to Quality

Each frame undergoes strict quality checks from manufacturing to finishing. We ensure strength, durability, and visual consistency in every product. Our focus on quality delivers trusted, long-lasting performance that meets the highest expectations in construction and design.

Customer Service

We support clients from consultation to installation. Our team offers expert advice, timely updates, and personalized assistance to ensure smooth experiences. At Manvik, we’re committed to satisfaction, making sure every project is efficient, successful, and well-supported.

Advanced Finishing

Frames are finished with baked-on coatings and anti-corrosive treatments for long-lasting performance. These finishes resist chipping, weather effects, and wear while maintaining a refined appearance—ensuring both functional durability and visual appeal in environments, indoor or outdoor.

Key Benifits

PPGI window frames can be easily installed as they are light in weight and are fabricated in advance before the actual construction. Most of the frames are designed with pre-punched holes and corner interlocking to facilitate on-site construction without necessarily welding. Hinges and locking systems can be easily fixed to the door frame through rivet technology to enhance the ease of installation.

Indeed, the use of PPGI window frames can be regarded as more environmentally friendly. While galvanization and pre-painting uses environment friendly coatings most of the time. Further, its long life cycle as well as the low need for maintenance results in minimum replacement, which is environmentally friendly in the construction industry.

The PPGI window frames do not corrode easily hence can be used in different areas of the world such as the areas with high humidity and areas near the sea. They are suitable for both hot and cold conditions, and are not affected by changes in temperature and weather conditions.

Latest Projects

Delivering Continuous Value to Our Clients Through Ongoing Product Development and Innovation.

Through our solar division we have established ourselves as the preferred market channel for some of the leading PV manufacturers around the globe. Our solar specialists work in tandem with the partners to improve the characteristics of products, shorten delivery time, and control cash conversion cycle.

Cost Effective

Visual Aesthetics

Good Sealing

Request A Quote

Quick Contact

Precision-engineered for superior style and durability. Explore our PPGI products.

Head office:

Rania chungi, Sirsa, Haryana

©2025 manvik door frames, All Rights Reserved. With Love by bonkersart