Understanding the Machinery Process

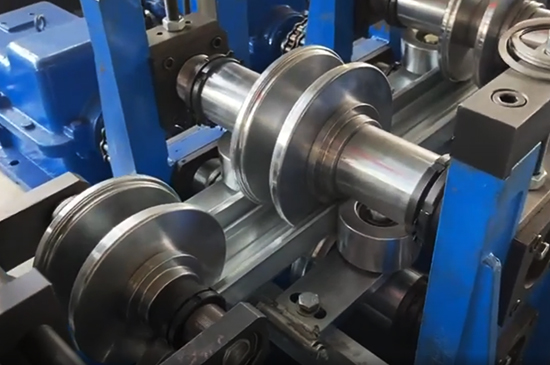

Our PPGI door frames are precision-crafted with advanced machinery, ensuring automation and superior quality.

Understanding the Machinery Process

Our PPGI door frames are precision-crafted with advanced machinery, ensuring automation and superior quality.

Overview!

Quality Powered by Advanced Machinery to Shape the Future of Frames

With every At Manvik, quality isn’t just a goal—it’s a commitment that starts with understanding every detail of our production process. As one of India’s trusted manufacturers of PPGI doors and window frames, we pride ourselves on crafting products that combine precision, durability, and beauty. From the raw steel coil to the final product, each step is carefully engineered to meet the highest standards.

We take the time to ensure that our frames are not only strong but also built to last, withstanding the test of time and the elements. Whether it's a home or a commercial building, our frames are designed to provide reliable support while enhancing the overall aesthetic. Here's how we turn hot-rolled steel into durable frames that power projects across India.

Challenge!

Proven Record Of The High Performance & Reliability

Our state-of-the-art facility in Sirsa, Haryana, features world-class infrastructure and advanced machinery, allowing us to create products that exemplify superior quality and durability. With two manufacturing units covering 9,000 sq. ft. and 40,000 sq. ft., we ensure meticulous quality testing and efficient warehousing and dispatching for all our offerings.

Extensive Manufacturing Units - Advanced machinery for high-volume.

Quality Testing Lab - Rigorous checks for reliable strength.

Warehousing & Dispatch - Streamlined logistics for timely delivery.

Skilled Workforce - Expert team ensures consistent quality.

1

Projects Completed

In Last 5 Years

In Last 5 Years

1

Qualified Employees

& Workers With Us

& Workers With Us

1

Happy Customers

Who Trusted Us

Who Trusted Us

1

Awards Milestones

Awarded To Us

Awarded To Us

Making Tomorrow Different Today.

Advanced Equipment Ensures

Timely, Satisfied Customers

Advanced machinery has been pivotal in expanding Manvik’s door and frame business across North India. Our modern equipment has significantly improved time management, ensuring timely delivery of services and enhancing customer satisfaction. Continuous innovation in our machinery has given us a competitive edge in the market.

Raw Material Selection

We carefully select high-quality hot-rolled steel coils to ensure optimal durability and performance.

Pickling Process

Steel coils undergo a pickling process to remove impurities and prepare for further treatment.

Cold Rolling

The cleaned steel is cold-rolled to achieve precise thickness and enhance its strength and flexibility.

Annealing

The annealing process softens the steel, restoring its ductility for easier shaping, creating and forming.

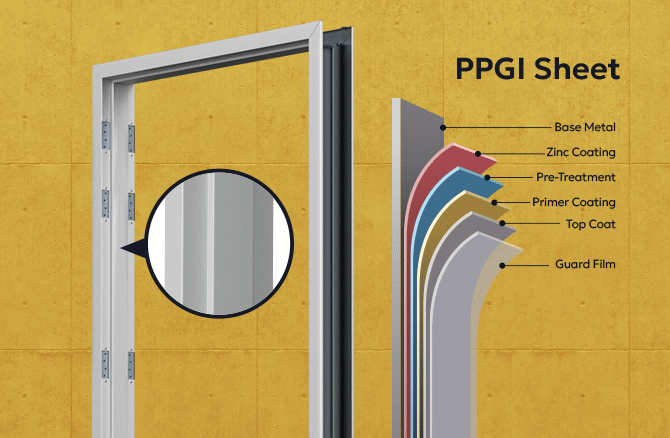

Galvanizing

Steel is hot-dipped in zinc to create a unique protective coating that prevents corrosion and rust.

Pre-Treatment

A chemical pre-treatment ensures excellent paint adhesion, providing a smooth surface for finishing.

Painting Process

Using advanced techniques, we apply high-quality paint that enhances aesthetics and adds protection.

Curing

The painted steel is cured in an oven, ensuring a highly durable bond between the paint and steel.

Precision Cutting

Our cutting-edge equipment precisely cuts the frames to specifications, ensuring a perfect fit for projects.

Quality Inspection

Each product undergoes thorough inspection, guaranteeing that every frame meets our quality standards.

99.9% Customer Satisfaction

based on 750+ reviews and 6,154 Completed Projects.

We offer our customers a range of services and perks so that they can upgrade their spaces easily.

Our services include:

Zinc-coated steel with pre-applied paint for durable finish.

Multi-layer coating resists rust, peeling, fading, and corrosion.

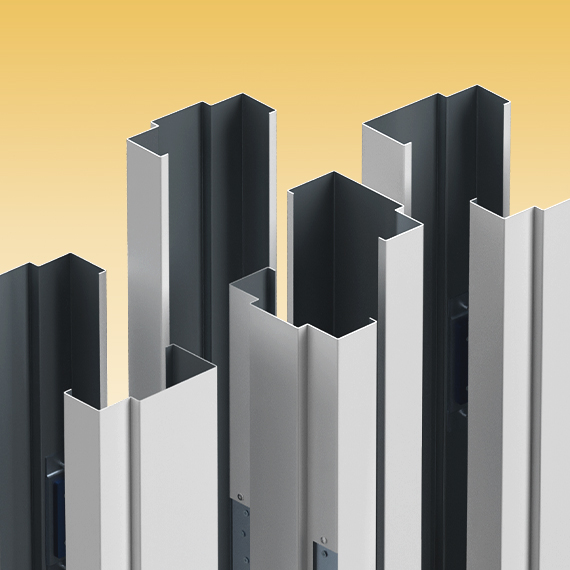

Rivet joints and embossed corners ensure strong, lasting frames.

Termite-proof, weather-stable, and protected during installation process

Quality and Satisfaction

Delivered with Every Order

When you are choosing us, stay assured seamless service right from the placing the order with to the installation. We strive to provide our valuable customers the highest quality products and exceptional service that they deserve while building the space of their dreams.

Versatile Applications of

Manvik PPGI Frames

Manvik’s PPGI doors and frames are ideal for residential, commercial, and industrial projects. They offer durability, corrosion resistance, and aesthetic flexibility, making them suitable for homes, offices, retail spaces, and heavy-duty environments requiring long-lasting, low-maintenance solutions.

Crafting Excellence in Every Frame

Adding a touch of delight and charm to houses

We enhance PPGI’s potential with advanced technology and meticulous craftsmanship. Our Sheet Thickness Measurement Tool provides consistent thickness, while advanced Roll Forming Machines create frames that fit seamlessly. Our frames have a centre partition that requires minimal welding, giving you a robust frame without compromising on aesthetics.

We ensure accurate measurements that saves you from the hassle fitting issues. Each frame comes equipped with an inside centre lock cap, adding an extra layer of security and functionality.

Built on Excellence

Frames Built with Trust, Powered by Technology, Perfected with Excellence

At Manvik, quality is at the core of everything we do. Through advanced machinery, precision engineering, and automated processes, we manufacture PPGI frames that combine exceptional durability with modern aesthetic appeal.

Our state-of-the-art technology ensures every frame meets the highest industry standards, delivering consistent strength and reliability. By sharing our production practices, we aim to build trust and transparency with our customers. Explore our range of PPGI frames and experience the excellence that defines every Manvik product.

Precision Engineering

Frames crafted with accurate dimensions for perfect fit and durability.

Automated Processes

Advanced forming lines ensure consistency, efficiency, and seamless production.

Quality

Assurance

Assurance

Every frame tested for strength, performance, and long-term reliability.

Quick Contact

Precision-engineered for superior style and durability. Explore our PPGI products.

Head office:

Rania chungi, Sirsa, Haryana

©2025 manvik door frames, All Rights Reserved. With Love by bonkersart