Know our Production Process

Our production process ensures quality through careful material selection, precise cutting, shaping, and proper assembly of frame components.

Know our Production Process

Our production process ensures quality through careful material selection, precise cutting, shaping, and proper assembly of frame components.

Overview!

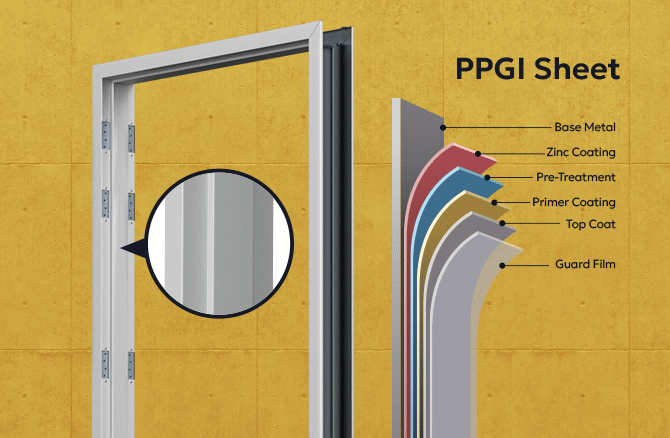

The Comprehensive Production Process of PPGI at Manvik

At Manvik, we believe that quality starts with a well-defined production process. Our journey to creating top-tier PPGI (Pre-Painted Galvanized Iron) frames is rooted in a commitment to excellence and innovation. From the moment we select premium hot-rolled steel coils to the final inspection of our finished products, each step is carefully crafted with precision and care. Our state-of-the-art machinery and skilled technicians work in harmony to transform raw materials into durable and aesthetically pleasing frames.

We understand that every detail matters, and that’s why we employ advanced techniques like cold rolling, hot-dip galvanizing, and precision cutting. Our goal is to deliver PPGI frames that not only meet but exceed expectations, ensuring they enhance your residential and commercial spaces for years to come. Join us on this journey of craftsmanship and quality!

Safety First!

Creating Excellence with Care and Confidence

Safety is paramount for our craftsmen working with machinery and materials. Essential measures include PPE such as gloves, goggles, and helmets to prevent injuries. Regular training ensures safe equipment handling and awareness of potential hazards. With proper guidance and first-aid readiness, our team is prepared for emergencies. By strictly following safety regulations, we ensure efficient work while protecting health and well-being.

Personal Protective Gear - Helmets, gloves, goggles for worker safety.

Machinery Safety Training -Skilled guidance for safe handling.

Equipment Safety Checks - Regular inspections for accident-free use.

Periodic Safety Audits - Routine checks to ensure hazard-free work.

1

Projects Completed

In Last 5 Years

In Last 5 Years

1

Qualified Employees

& Workers With Us

& Workers With Us

1

Happy Customers

Who Trusted Us

Who Trusted Us

1

Awards Milestones

Awarded To Us

Awarded To Us

Modern Problems, Modern Solutions

Transforming Operations with Modern Efficiency and Lasting Excellence

With the advent of modern technology, our operational methods have transformed significantly. Many manual tasks have been replaced by highly engineered machinery, allowing us to enhance efficiency and provide prompt, reliable services. Our commitment to embracing innovation means we can meet the evolving needs of our customers while maintaining the highest standards of quality.

Discover how our machines operate in the "Process of Machines" section.

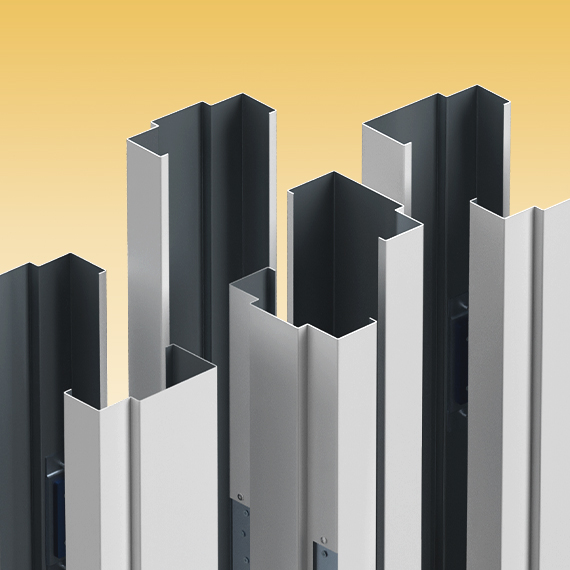

Roll Forming Machine

Transforming metal effortlessly, creating perfect profiles for every project without compromise.

No Welding

Say goodbye to weak joints; our designs ensure strong and hard strength and highly durability without welding.

Rivet Technology

Innovative rivet connections provide unmatched stability, making your frames more reliable and long-lasting.

Embossed Corners

Stylish embossed corners add elegance and strength, enhancing both form and function.

Lamination

Our lamination process ensures vibrant colors and long-lasting shield protection against the elements.

Seamless Installation

Experience hassle-free installation with components designed to fit together seamlessly.

Lock Hole Position

Thoughtfully designed lock hole positioning simplifies installation, enhancing security and reliability.

Measurement Accuracy

Precision matters most; we guarantee exact accuracy in all dimensions, ensuring a flawless, reliable, and perfect fit.

99.9% Customer Satisfaction

based on 750+ reviews and 6,154 Completed Projects.

We offer our customers a range of services and perks so that they can ugrade their spaces easily.

Our services include:

Zinc-coated steel with pre-applied paint for durable finish.

Multi-layer coating resists rust, peeling, fading, and corrosion.

Rivet joints and embossed corners ensure strong, lasting frames.

Termite-proof, weather-stable, and protected during installation process

Quality and Satisfaction

Delivered with Every Order

When you are choosing us, stay assured seamless service right from the placing the order with to the installation. We strive to provide our valuable customers the highest quality products and exceptional service that they deserve while building the space of their dreams.

Versatile Applications of

Manvik PPGI Frames

Manvik’s PPGI doors and frames are ideal for residential, commercial, and industrial projects. They offer durability, corrosion resistance, and aesthetic flexibility, making them suitable for homes, offices, retail spaces, and heavy-duty environments requiring long-lasting, low-maintenance solutions.

Crafting Excellence in Every Frame

What Sets Manvik's Production Process Apart

At Manvik, our production process is distinguished by our commitment to innovation and quality. We leverage advanced machinery, such as roll forming machines, which eliminate the need for welding, ensuring stronger and more reliable frames. Our use of rivet technology, embossed corners, and precision measurement guarantees exceptional durability and aesthetic appeal.

Additionally, our seamless installation and rust protection features reflect our dedication to providing superior products that meet the evolving needs of our customers.

Commitment to Excellence

Accuracy, Strength and Innovation at the Core of Every Frame

At Manvik, we take pride in our comprehensive production process for PPGI frames. From selecting premium raw materials to implementing advanced machinery and rigorous quality control, every step is designed to create products that exceed expectations.

We invite you to explore our range of PPGI frames and experience the Manvik difference for yourself.

Precision Engineering

Frames crafted with accurate dimensions for perfect fit and durability.

Automated Processes

Advanced forming lines ensure consistency, efficiency, and seamless production.

Quality

Assurance

Assurance

Every frame tested for strength, performance, and long-term reliability.

Quick Contact

Precision-engineered for superior style and durability. Explore our PPGI products.

Head office:

Rania chungi, Sirsa, Haryana

©2025 manvik door frames, All Rights Reserved. With Love by bonkersart